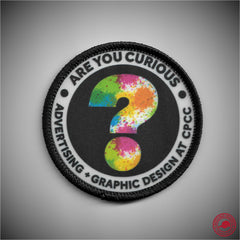

I always get "you have too many colors."

The ability to offer tried and true technique standards along with modern shiny bling is what we call Luxurious Rebellion and what we hope to bring to our client's tool box , letting our designers help them use these mediums to stimulate imagination and create patches that will turn heads, beg to be touched, and create conversation.

We currently offer three specialty techniques and we are sure that one if not a combination of these techniques will have heads turning and your brand being the word on the street, as well as in the board room.

Sublimation:

Sublimation printing uses your full color artwork that is then printed onto white polyester patch material. The process uses the science of sublimation, in which heat and pressure are applied to explode the dye into the fabric. The end result of the sublimation patch is a nearly permanent, high resolution, full color print. Because the dyes are infused into the polyester patch material at the molecular level, rather than applied at a topical level like screen printing, the prints will not crack, fade or peel from the polyester patch material.

This allows us to work with any image as long as it is saved at a high resolution. Never again be told by an art department that your logo or design has too many colors to be produced, with sublimation printing we can produce designs that otherwise would never be created.

We use two different types of polyester patch material to get the best result depending on your needs. Satin polyester patch material is best used for graphics and gives a smooth appearance great for photos and art, while the Twill polyester patch material has the look and feel of a true patch because of the groves in the twill material.

Woven, embroidered, chenille, and sequenced patches are limited by either colors, size, or cost. Sublimation is able to achieve satisfactory results and offer a more economical solution. Often times our clients use sublimation to achieve small lettering that cannot be done in embroidery at the same or lower cost of embroidery. They simply heat press the sublimation patch in place or get the patch with no border and no backing, then use machine embroidery to sew it to the garment as if it were an applique.

Like all of our patches we apply a backing such as a sticker backing and sew the embroidered border for a finished patch that is ready to be applied to a garment or sold in retail. Let our experienced team of designers and applicators hep you decide the best way to bring the unlimited printing abilities of the sublimation printing technique to your next creative patch project.

Pros:

- Unlimited CMYK colors.

- Great for high resolution projects.

- Very economical for smaller qty orders.

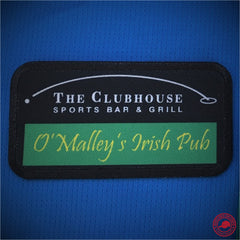

- Good option Vs embroidery (see O'Malleys Irish Pub example below)

Cons:

- Results depend on output resolution of at least 300 DPI.

- Small lettering and details cannot be created.

- Difficult to achieve rich black.

- Colors can loose some vibrancy.